Written by Erich Knemeyer

After 30+ years of looking at failed coils in the field, I’ve seen how frustrating it can be dealing with heating problems that lead to costly and unexpected shutdowns. Many of these issues stem from poorly designed or undersized heating coils. Heating coils are the workhorses of your heating system, but if your coils aren’t up to the task, you’ll start to experience some serious consequences. I have personally seen these six common signs that your heating coils are not properly supporting your application.

Signs that your heating coils might be the problem:

1. Freezing Lines

If you notice ice forming on your heating coils or piping, it’s a strong indicator they are not the right size or design for your application. Ice buildup significantly reduces the coils’ ability to transfer heat, leading to decreased efficiency and potential damage to your equipment. This issue can arise when the coils are too small to handle the required heat load, if the airflow is insufficient or stratified, or if there is improper drainage.

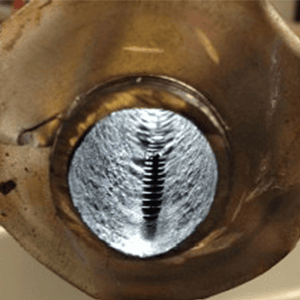

Have you noticed splitting in your coil tubes or piping? It would look something like the image below. Ice or freezing on your system tells you that your coils need to be evaluated and most likely should be replaced.

This image is an example of coil splitting.

This image is an example of a busted steam trap from freezing.

2. Corrosion

Whenever I walk into a facility and see rust on the heating coils, I know there’s a problem. External corrosion happens when coils are exposed to moisture and oxygen over time. This is more common in humid, outdoor environments or when the coils aren’t properly maintained.

If your coils aren’t designed to withstand the environmental conditions they’re exposed to, they will corrode faster. Proper coatings or corrosion-resistant materials are crucial in humid or salty environments. Corrosion indicates that the coil isn’t suitable for the application, leading to inefficiencies and potential premature failures. Making sure you have the right coil design for your specific needs can prevent corrosion and extend the life of your equipment.

I’ve seen internal corrosion develop from the lack of proper air removal mechanisms causing acids to form inside the coils. This has a large negative impact on heat transfer and leads to premature failure of the coil tubes. This often happens when air and condensate mix, creating corrosive acids. My advice to you is to select a coil design with effective air removal to prevent internal corrosion and extend the life of your system.

This image is an example of external corrosion.

This image is an example of internal corrosion.

3. Erosion

I’ve seen firsthand how high-velocity water can wreak havoc on heating coils. When water rushes through the coils too quickly, it gradually wears down the coil walls, leading to leaks, reduced performance, and noisy operations. Erosion often results in thinning of the coil walls, which can cause pinhole leaks. If you hear hissing or gurgling sounds, it’s a clear sign that erosion is occurring. To combat this, choose coil designs built to handle appropriate water velocities, minimizing the risk of erosion and extending the lifespan of your equipment.

4. Increased Energy Consumption

Are you like me? Each time I fill my gas tank I do a quick calculation on my MPG to see if there are any issues with my car. Using the same principle, if your energy bills are higher than usual, it could be a sign that your heating system is working overtime to keep up. Inefficient coils force the system to use more energy to maintain the desired temperature, leading to higher costs and a bigger environmental impact. Upgrading to properly sized and designed coils can improve efficiency and reduce energy consumption.

5. Inconsistent Heating

In my experience, inconsistent heating is a major red flag. When some parts of your facility are colder than others, it can disrupt your workflow, impact product quality, and make your employees uncomfortable. This uneven heating is a sign that your coils aren’t distributing heat properly, usually from having the wrong coil for your application. Ensuring that your coils are correctly sized and positioned is crucial for achieving uniform heating.

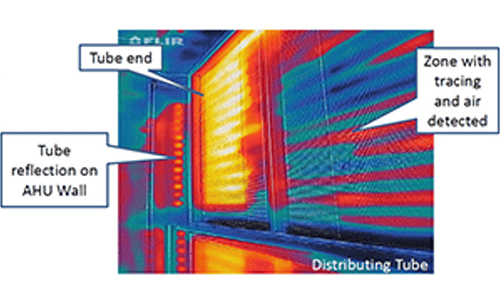

This issue isn’t limited to HVAC applications; it’s also a significant concern in process applications. Inconsistent process heating can indicate a reliability issue with your coils. I’ve encountered situations where one side of the coil is extremely hot, while the other side is so cold you can put your hand on it. Addressing these issues with the right coil design can help maintain consistent temperatures and improve overall system performance.

This is a thermal image of a standard steam coil. It’s hot on the left side of the image, but on the right, it’s cold showing inconsistent heating throughout.

6. Premature Breakdown

Constant repairs and unexpected downtime are major headaches. A faulty coil design can lead to premature failure and breakdowns, disrupting your operations and costing you money. Look for signs such as frequent repairs, unusual noises, or decreased performance. Identifying and addressing coil issues early can prevent costly breakdowns and extend the lifespan of your heating system. Our team has been on the receiving end of many of these calls through the years and can provide knowledge and experience to come up with a quick reliable solution based on field conditions. Let’s minimize these situations together.

Experiencing any of these signs? Check on your coils—they might be an easy fix for improving your system’s efficiency and reliability. Regular maintenance, proper selection, and timely replacements are key to avoiding these issues. Request an inspection from our experts and we’ll identify potential issues and recommend the best solutions to enhance your heating system’s performance.

About Erich Knemeyer | Technical Specialist at Merlo Energy

With over 33 years of experience in steam, condensate, and hot water systems, Erich Knemeyer possesses extensive knowledge and expertise in optimizing heating system efficiency. He holds a BS in Engineering Physics from Miami University in Ohio and has dedicated his career to assisting customers in troubleshooting their steam and heating systems. Currently, Erich collaborates with engineers and contractors, providing support in design development and the startup process.

Select the Right Coil Design for Your Application

Learn about our available coil designs to select the right fit for your needs.

Webinar - Coil Failures: Design & Piping Solutions

Discover the common causes of extended surface heat transfer coil failures and how to prevent them.