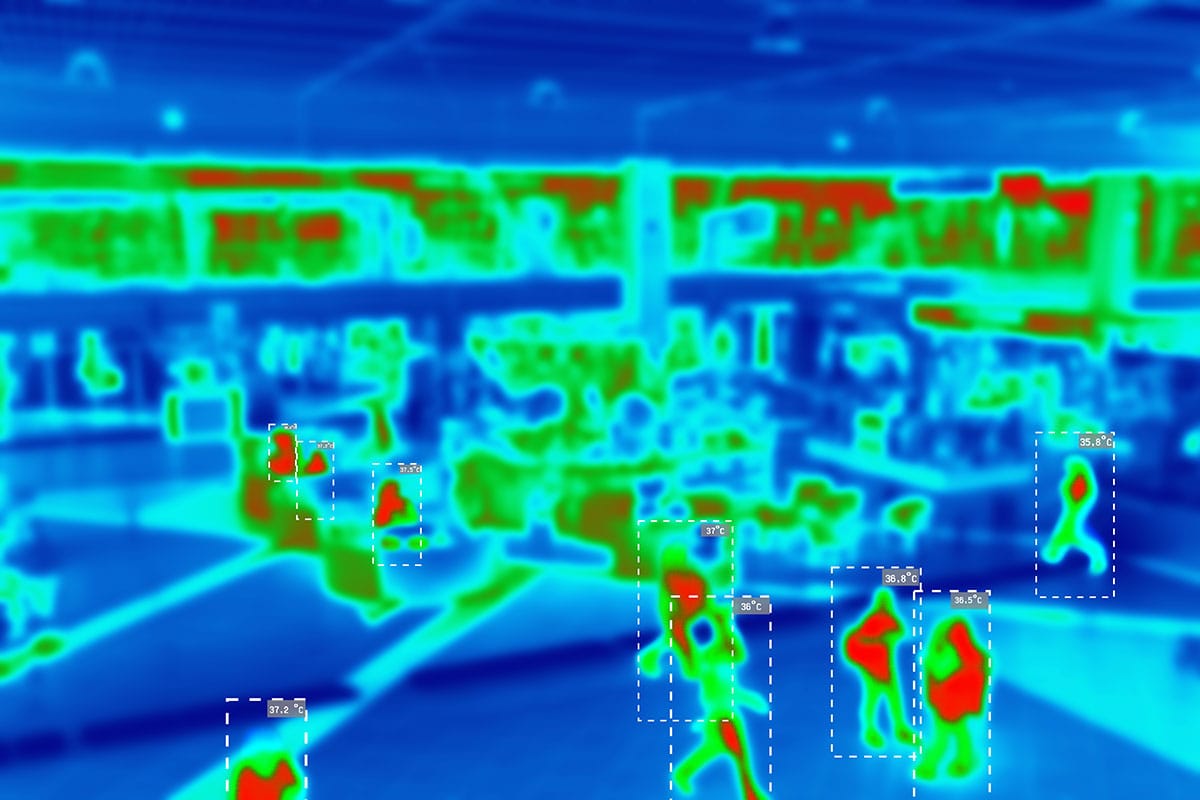

Thermal System Audits & Mapping Studies

Identify areas where energy is being wasted in your facility.

Get a full diagnostic review of inefficient heating and cooling systems, poor insulation, or inadequate ventilation with a thermal system audit or mapping study. The information Merlo Energy provides after the audit will be used to develop and implement energy efficiency measures that can save money and reduce greenhouse gas emissions.

To conduct these audits, Merlo Energy partners with Armstrong International’s thermal utility system engineers that are Certified Energy Managers (CEM) and contributors to the ASME EA-3-2009 standard and UNFCCC/CDM methodology AM0017. The engineering team requires a minimum of 4-5 days onsite depending on data availability and the size of the facility. Data evaluation and presentation takes about 12-16 weeks to prepare final reports for plant personnel.

Thermal System Audits offer comprehensive analysis of the following areas:

- Steam generation: boiler, feedwater, blow-down and make-up water

- Steam load estimation: estimating present, actual steam demand required to meet typical demand

- Steam distribution: steam pipe sizing, pipeline layout, steam pressure reducing stations, steam leaks

- Steam users: study of process, steam load estimation in each section, temperature/pressure control, ideal steam usage, plant steam mass balance

- Condensate collection and return system: back pressure, water hamper, condensate return unit utilization, flash steam evaluation etc.

- Identify projects (ECMs – Economic Conservation Measures): conceptual design only, estimated energy savings +/- 10%, estimated projects +/- 30%

Benefits of a thermal system audit or mapping study

- Improve productivity & reliability

- Reduce energy costs

- Improve efficiency and system optimization